DONGGUAN XINRUN SILICONE NEW MATERIALS LIMITED

GLOBAL LEADING MANUFACTURER OF MOLDMAKING CASTING MATERIALS FOR MORE THAN 10 YEARS

Hotline: 0086-0769-89600400 Email: info@xrsil.com Skype: info@xrsil.com

GLOBAL LEADING MANUFACTURER OF MOLDMAKING CASTING MATERIALS FOR MORE THAN 10 YEARS

Hotline: 0086-0769-89600400 Email: info@xrsil.com Skype: info@xrsil.com

Step one: Preparing the material

500g of liquid silicone rubber & 10g of catalyst

Strap clamp

Wood ‘Master block ‘this will define the size of your casting blank

Wood frame

Glad wrap / food plastic film

Wood or corian board here I use an off cut of 3m/m MDF

1 Potato

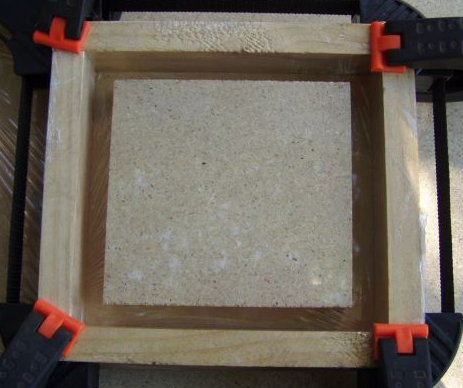

Step two:

Cut all your wood to size for the frame here I’m doing a 1” mould by 5 1/4”x 5 1/2” ( size of the master block ) I will have then 5 blanks 1” x 5 ¼” . The wood frame is 2 length 6 ¼” x ¾” thick x 1 ½”high and 2 length 8 ½” x ¾” thick x 1 ½”high, Wrap all your wood pieces including the 3 m/m MDF base with glad wrap then make your frame.

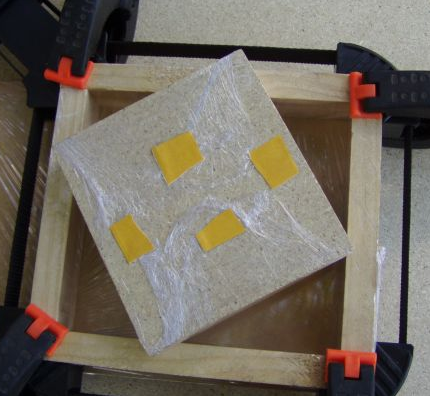

Step Three:

Secure the master block to the board with double side sticky tape

Step Four:

Cut the RTV nozzle cartridge to a wide opening and start the edges while holding the master block, make sure that the nozzle is in the silicone to prevent air bubbles, cover the top who will be the bottom of the mould and smooth the edge with the potato ( silicone doesn’t stick to potato starch ) then cover with glad wrap to smooth the surface and let it cure 24 hours.

Step Five:

After 24 hours you can undo the frame and peel off each side of the mould, you have to go very easy as the silicone still fresh and can be tear easily

Base removed ( nice smooth edges )

2018-06-26